Heeft u geen account? Meld u gratis aan

Voor adverteren op

Interesse om verkoper te worden? Ontvang informatie

Heeft u geen account? Meld u gratis aan

Voor adverteren op

Interesse om verkoper te worden? Ontvang informatie

Heeft u geen account? Meld u gratis aan

Voor adverteren op

Interesse om verkoper te worden? Ontvang informatie

Downhole Tools

Ook bekend als:

Wireline Tools, Slickline ToolsBuy

In Stock

Product & Service

New

API

Air Freight

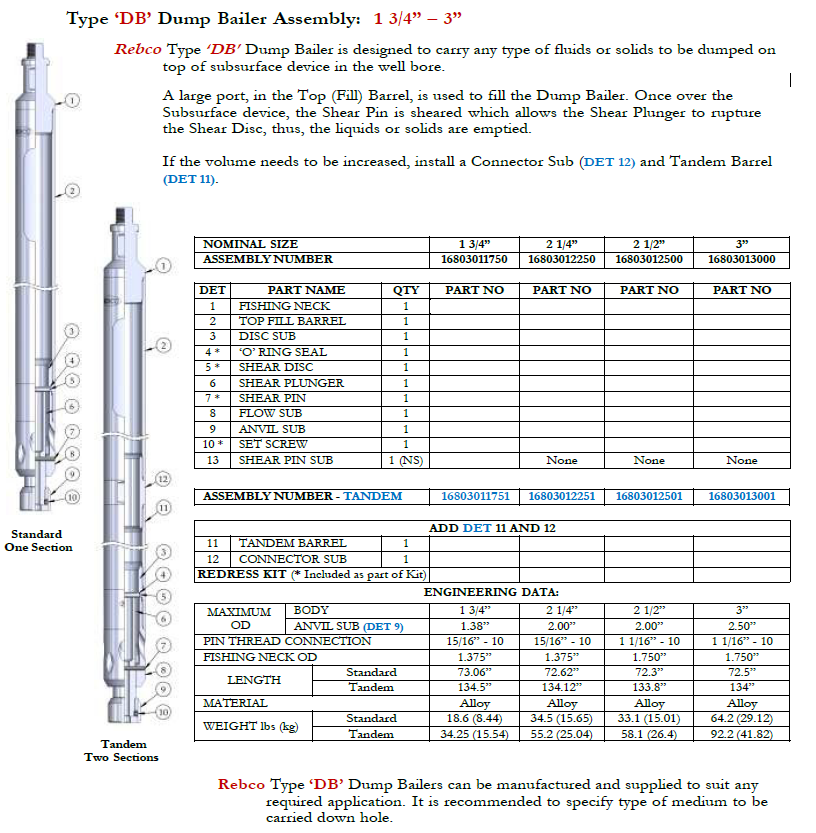

Titel:

Dump BailerModel Nummer:

VariousBeschikbaarheid:

In StockLevertijd (weken):

2In Stock

Transactie Type

BuyStaat

NewGewicht

Various lbsLocatie

NetherlandsBedrijfstype

Product and Service ProviderKwaliteitsgarantie

APIPrijs

Request for QuoteMateriaal

SteelMerknaam

HOCAVerzending

Air FreightNotities

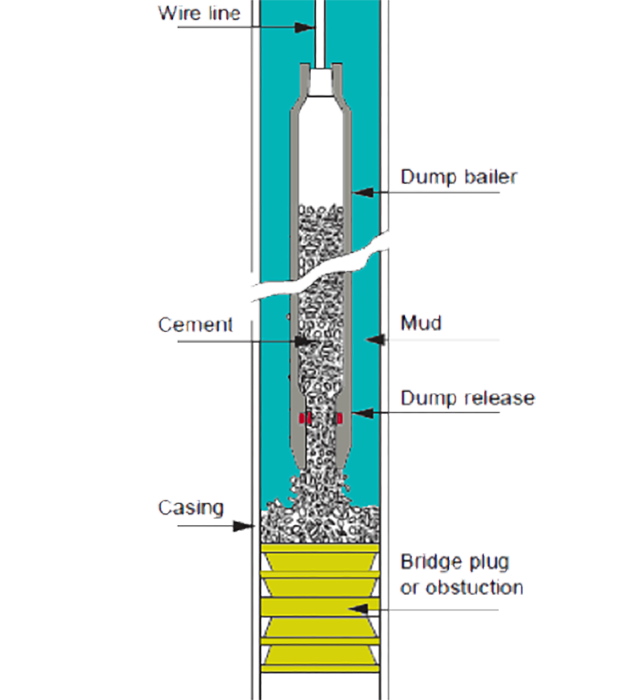

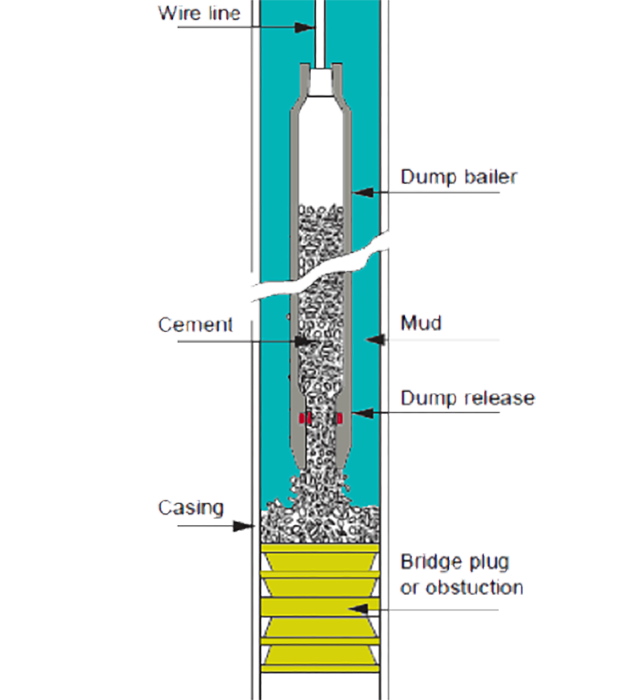

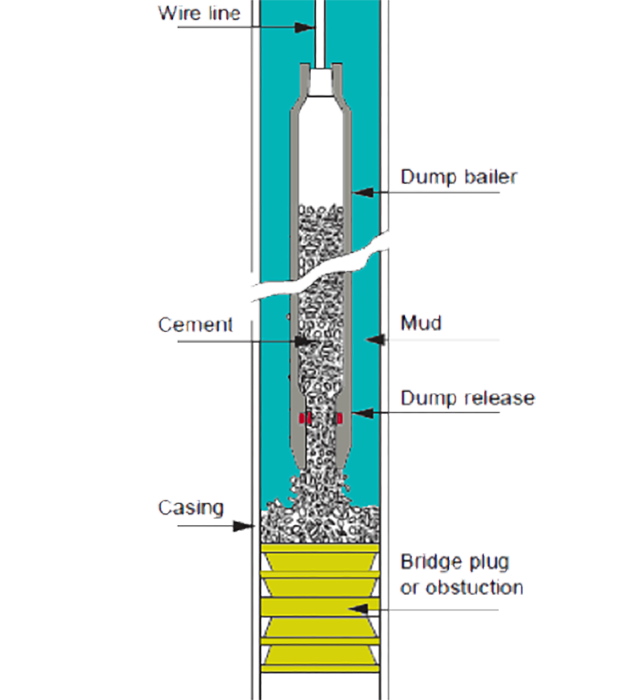

A Dump Bailer can carry fluids or solids and dump them downhole by emptying the bailer.

![]() Hoca Oil Tools in Zwartemeer

Hoca Oil Tools in Zwartemeer

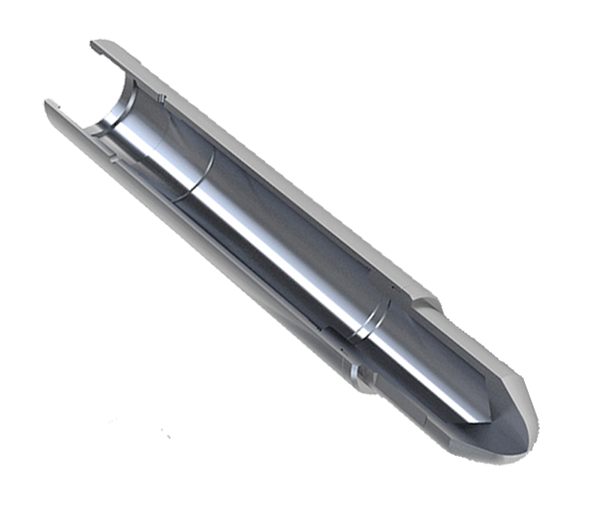

Maximize Well Integrity and Performance with HOCA Oil Tools' Tubing Drifts In the complex and demanding environment of oil and gas extraction, ensuring the integrity and functionality of downhole tubing is paramount. At HOCA Oil Tools, we understand these challenges and are dedicated to providing solutions that enhance the safety, efficiency, and productivity of your operations. Our Tubing Drifts stand out as a testament to our commitment to quality and precision in downhole slick line tools. HOCA’s Tubing Drifts: Precision Engineered for Optimal Performance Tubing Drifts are essential tools designed to ensure the clear passage within downhole tubing, preventing costly blockages and ensuring the smooth operation of subsequent downhole tools and processes. Made from high-quality materials and engineered to meet rigorous industry standards, HOCA Oil Tools’ Tubing Drifts are designed to provide accurate measurements and clearances, ensuring your tubing is free from obstructions and ready for operation. Experience the HOCA Difference in Downhole Operations At HOCA Oil Tools, our mission is to provide the oil and gas industry with downhole tools that exceed industry standards and meet the complex demands of modern drilling and extraction processes. Our Tubing Drifts embody this mission, offering precision, reliability, and efficiency to enhance your downhole operations. Incorporating HOCA’s Tubing Drifts into your downhole tool inventory signifies a step towards optimized well maintenance, enhanced safety, and increased operational efficiency. With HOCA Oil Tools, you gain more than just a supplier; you gain a partner dedicated to supporting your success with innovative solutions and expert service. Choose HOCA Oil Tools’ Tubing Drifts for your downhole operations and join the ranks of satisfied customers who trust our tools to maintain the highest standards of well integrity and performance. Elevate your downhole operations with HOCA Oil Tools – where quality meets innovation.

Buy

In Stock

Product & Service

New

API

Air Freight

![]() Hoca Oil Tools in Zwartemeer

Hoca Oil Tools in Zwartemeer

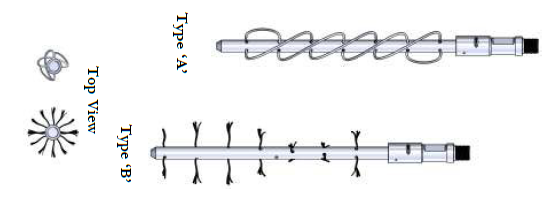

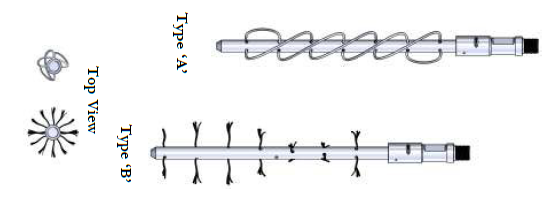

Enhancing Well Integrity with HOCA Oil Tools B.V.'s Slickline Gauge Cutters In the specialized field of oil and gas exploration and production, maintaining well integrity and efficiency is non-negotiable. At HOCA Oil Tools B.V., we are at the forefront of providing innovative solutions that cater to the complex needs of wellbore maintenance. Our comprehensive array of Slickline Gauge Cutters represents our commitment to excellence and precision, designed to tackle diverse challenges within the tubing string. Multi-functional and Versatile Applications: Our Rebco Type ‘A’ Gauge Cutters serve as multi-functional tools indispensable in the upkeep and maintenance of tubing strings. They are meticulously designed for removing paraffin, corrosion, and other foreign materials from the internal surface of the tubing, ensuring unimpeded flow and operational efficiency. The versatility extends to gauging and tagging obstructions, identifying and marking landing nipples, and preparing wells for the safe insertion of sub-surface controls. These applications underscore the critical role our gauge cutters play in well maintenance and diagnostics, emphasizing their value in operational planning and safety. Customizable Sizes for Precise Operations: Understanding the diversity of wellbore sizes and operational requirements, HOCA Oil Tools offers Gauge Cutters ranging from 1 inch to 7 inches in diameter. This extensive range ensures that all operational needs are met, from smaller interventions to large-scale maintenance tasks. Each gauge cutter can be customized to specific operational needs, ensuring that whatever the well condition or requirement, we have the right tool for the job. How to Order and Customization Options: Our ordering process is streamlined to ensure that you receive the gauge cutter that best suits your operational needs. Gauge cutters are ordered by part number, designated by the outer diameter to three decimal places, ensuring precision and compatibility with your specific well conditions. Additionally, we offer customization options for thread and fishing neck lengths, accommodating unique operational requirements and ensuring that our tools integrate seamlessly with your existing equipment. In conclusion, HOCA Oil Tools B.V. remains committed to providing the oil and gas industry with superior quality tools and customer service. Our Slickline Gauge Cutters are a testament to this commitment, offering unparalleled versatility, efficiency, and reliability in wellbore maintenance operations. Choose HOCA Oil Tools for your downhole needs, and experience the difference that quality, innovation, and precision can make in optimizing your well performance

Buy

In Stock

Product & Service

New

API

Air Freight

![]() Hoca Oil Tools in Zwartemeer

Hoca Oil Tools in Zwartemeer

Achieve Superior Wellbore Cleanliness with HOCA Oil Tools' Wire Brush In the demanding realm of oil and gas extraction, the cleanliness and integrity of wellbores are paramount for operational success. Recognizing this critical need, HOCA Oil Tools has developed a premier solution: the Wire Brush, an essential component of our comprehensive downhole slick line tools portfolio. Designed to tackle the toughest wellbore contaminants, our Wire Brush is engineered for excellence, ensuring your operations maintain peak efficiency and safety. HOCA's Wire Brush: Pioneering Downhole Cleanliness At HOCA Oil Tools, we understand that every downhole environment poses unique challenges. That's why our Wire Brush is meticulously crafted to remove deposits, scale, and other obstructions with unmatched efficiency. Constructed from durable materials capable of withstanding harsh downhole conditions, the HOCA Wire Brush is your ally in maintaining wellbore integrity and optimizing production flow. Elevating Downhole Maintenance with HOCA Oil Tools Innovation, quality, and customer satisfaction are at the core of HOCA Oil Tools' mission. Our Wire Brush exemplifies these values, providing a solution that not only meets but exceeds the demands of modern downhole operations. With the HOCA Wire Brush, operators can expect a level of cleanliness and efficiency that sets new industry standards. Adopting the HOCA Wire Brush into your downhole cleaning regimen is an investment in your operation's future. It signifies a commitment to operational excellence, safety, and cost-effectiveness. Our dedicated team at HOCA Oil Tools is committed to supporting your success by providing superior downhole solutions that address the specific challenges of the oil and gas industry. Embrace the future of downhole maintenance with HOCA Oil Tools’ Wire Brush – your solution for maintaining pristine wellbores and maximizing operational outcomes. Experience the difference that comes with using tools crafted for excellence and backed by an unwavering commitment to your operational success. Choose HOCA Oil Tools for your downhole needs and join the ranks of industry professionals who trust our Wire Brush to keep their operations running smoothly, safely, and efficiently.

Buy

In Stock

Product & Service

New

API

Air Freight

![]() Hoca Oil Tools in Zwartemeer

Hoca Oil Tools in Zwartemeer

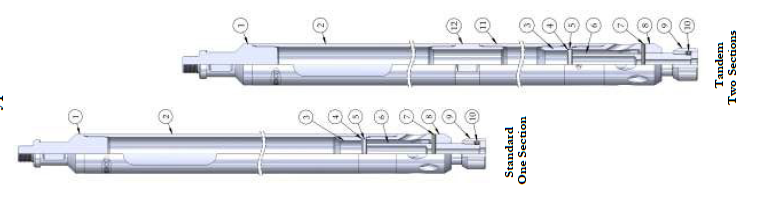

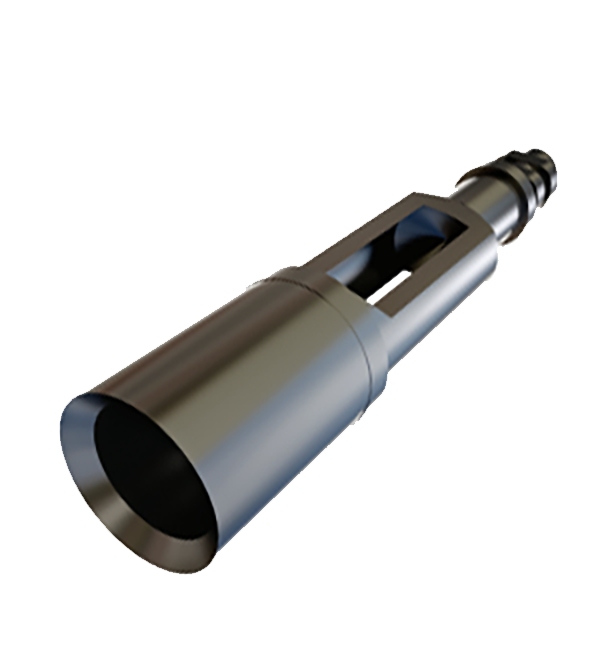

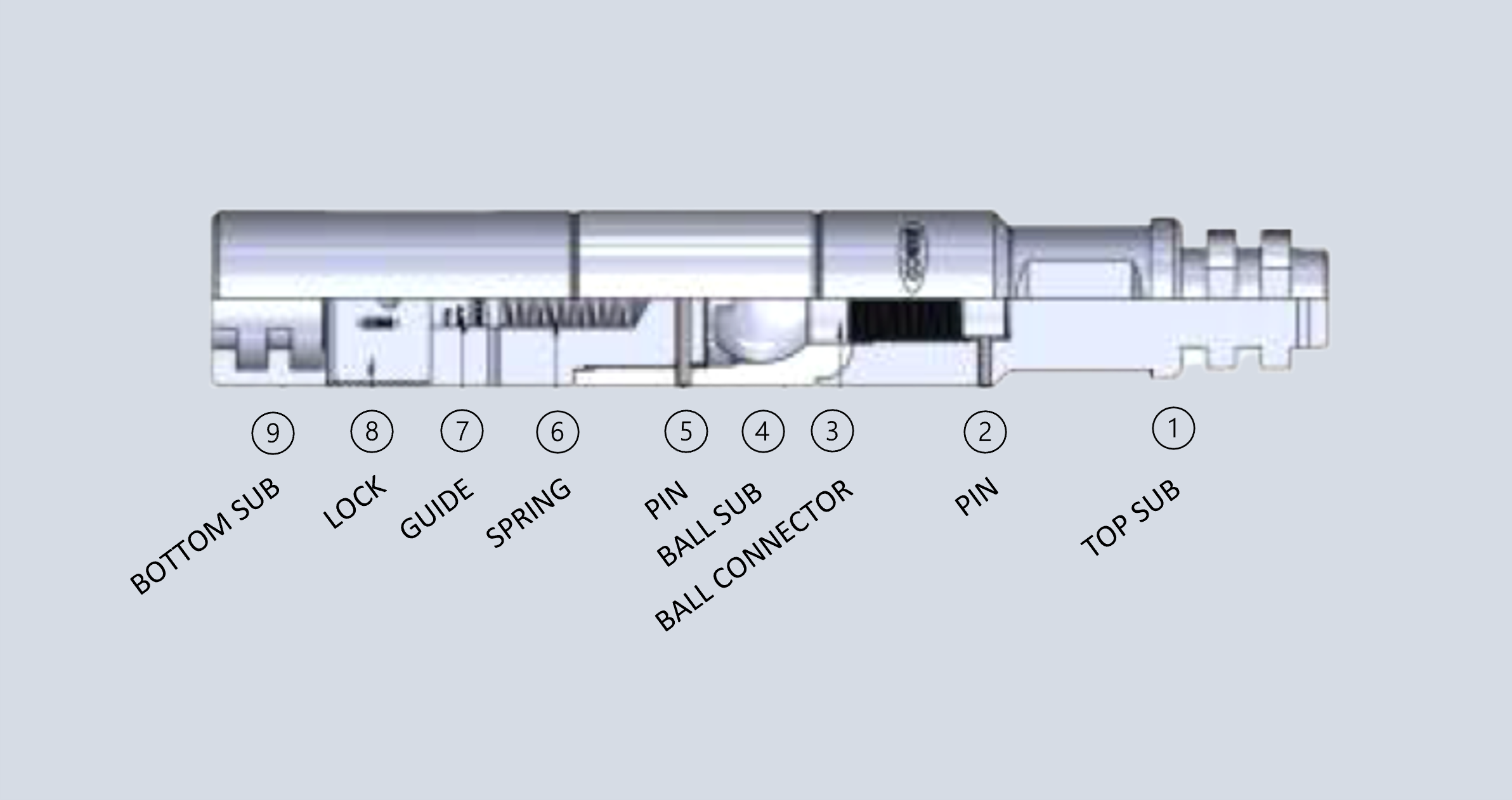

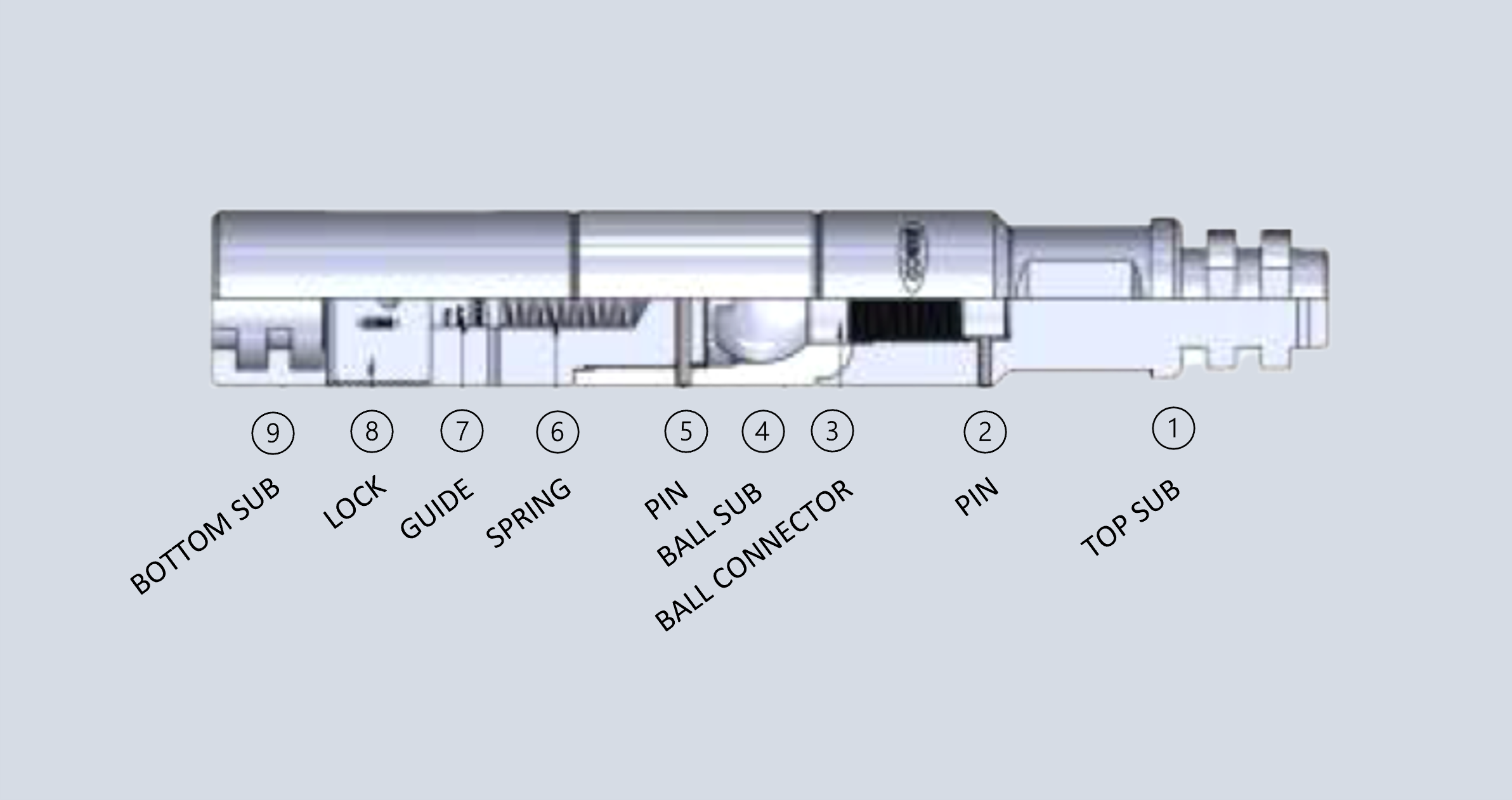

Unlocking Efficiency in Downhole Operations: HOCA Oil Tools B.V.'s Advanced Slickline Swivel Joints In the dynamic landscape of downhole operations, the role of slickline swivel joints becomes pivotal in ensuring seamless, efficient, and safe wireline operations. HOCA Oil Tools B.V., a renowned name in the oil and gas industry, stands at the forefront of delivering cutting-edge slickline solutions. Our array of slickline swivel joints is designed to meet and exceed the operational demands and challenges faced by our clients. Pioneering Slickline Swivel Joints: HOCA Oil Tools B.V. offers an extensive range of slickline swivel joints, including the Type ‘HO’ and ‘HD’ swivel joints, engineered to minimize wireline twisting during downhole operations. This not only enhances safety but also improves operational efficiency by reducing the risk of wireline entanglement and breakage. Key Benefits of Our Slickline Swivel Joints: Reduced Wireline Twisting: Our swivel joints significantly reduce the twisting of wireline, thus minimizing the risk of operational downtime and wire breakage. Enhanced Operational Safety: By preventing wireline kinks and twists, our swivel joints contribute to safer downhole operations, protecting both personnel and equipment. Increased Efficiency: Smooth wireline operations ensure quicker job completion and reduced non-productive time. Durability and Reliability: Made from high-grade materials, our swivel joints withstand harsh downhole conditions, ensuring long service life and reliability. Versatility: Available in various sizes and configurations, our swivel joints cater to a wide range of downhole requirements and wireline types. Ease of Integration: Designed for easy integration into existing tool strings, our swivel joints facilitate seamless operations without the need for extensive modifications. Main Features of HOCA's Slickline Swivel Joints: Type ‘HO’ Swivel Joint: Designed to minimize wireline twisting, available in sizes from 1” to 2 1/2", with threaded connections for easy installation. These swivel joints feature top sub, pin, ball connector, ball sub, and bottom sub components, ensuring robust performance and ease of maintenance. Type ‘HD’ Swivel Joint: Similar to the Type ‘HO’ but designed for even more demanding environments, with ‘QLS’ - ‘RQLD’ connections, providing additional strength and durability. These swivel joints are also available in sizes from 1 1/2” to 2 1/2", tailored for heavy-duty operations. At HOCA Oil Tools B.V., we understand the complexities of downhole operations. Our slickline swivel joints are a testament to our commitment to innovation, safety, and efficiency. Embrace the future of wireline operations with HOCA, where performance meets reliability. Contact us today to learn more about how our slickline solutions can optimize your operations.

Buy

In Stock

Product & Service

New

API

Air Freight

![]() Hoca Oil Tools in Zwartemeer

Hoca Oil Tools in Zwartemeer

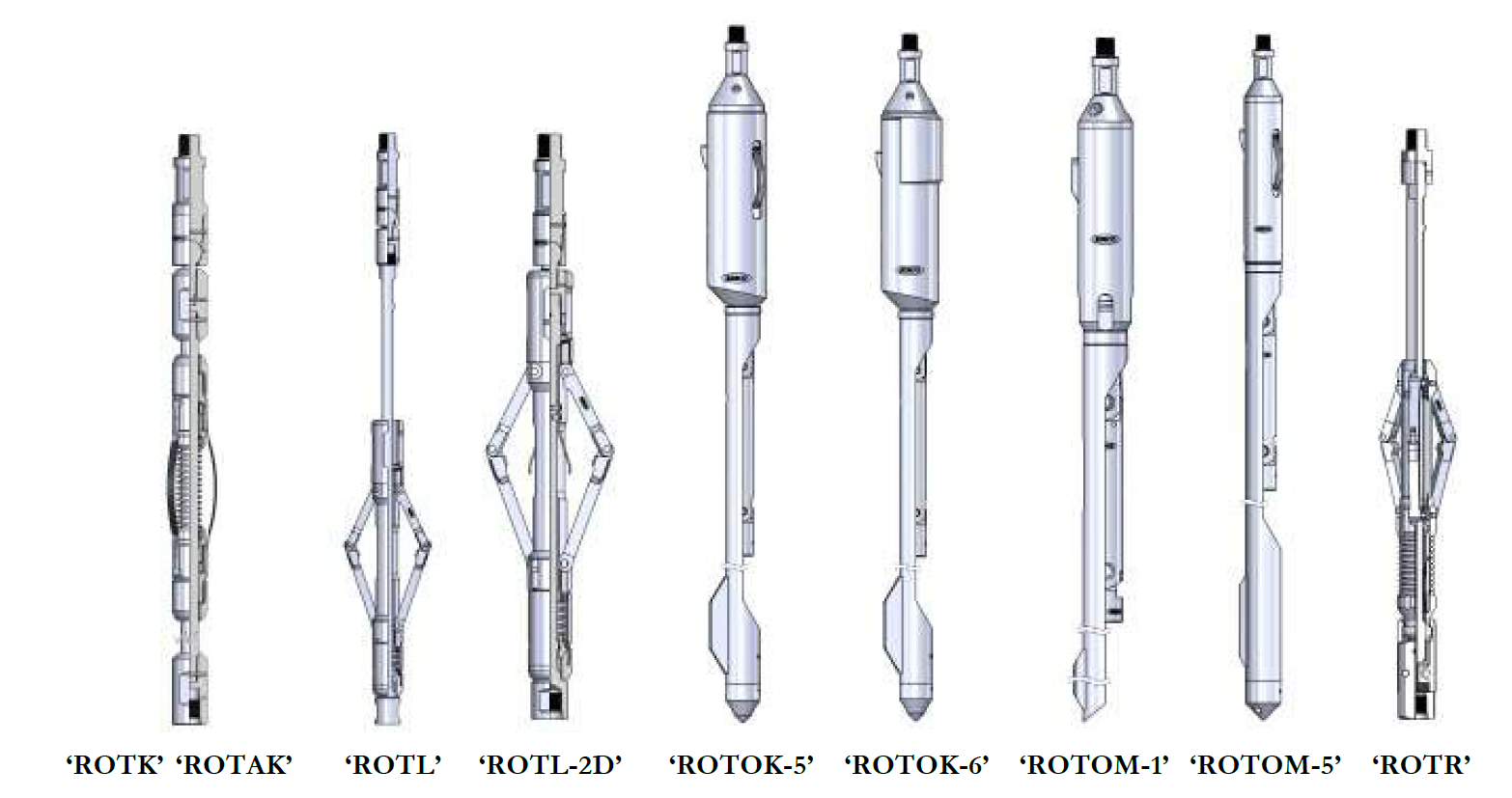

Maximize Downhole Efficiency with HOCA Oil Tools' Advanced Kickover Tools In the highly specialized realm of oil and gas production, achieving operational precision and efficiency is critical. HOCA Oil Tools responds to this need with our superior line of Kickover Tools, specifically designed to enhance gas lift operations and optimize production rates. Our Kickover Tools are engineered to facilitate the precise installation and retrieval of side pocket mandrels and other downhole control devices, ensuring seamless well performance and maximizing production. HOCA's Kickover Tools: Engineered for Excellence HOCA Oil Tools' Kickover Tools are the epitome of innovation in downhole technology. Designed for compatibility with a range of wellbore sizes and specifications, our tools are crafted to offer unmatched precision, durability, and ease of use. Whether you are installing new equipment or retrieving existing devices, our Kickover Tools provide the reliability and efficiency needed for successful downhole operations. Experience the HOCA Oil Tools Advantage Choosing HOCA Oil Tools’ Kickover Tools means opting for a brand synonymous with quality, innovation, and reliability. Our commitment to excellence ensures that our products meet the high standards demanded by the oil and gas industry, providing our clients with the tools they need to succeed in their downhole operations. By integrating our Kickover Tools into your operational toolkit, you gain not just superior downhole equipment but also a strategic advantage in your production operations. With HOCA Oil Tools, you partner with a company dedicated to supporting your success with cutting-edge solutions and comprehensive service. Opt for HOCA Oil Tools for your downhole needs and join the ranks of satisfied clients who trust our Kickover Tools to enhance their operational efficiency and well performance. Partner with us, and harness the power of advanced downhole solutions designed for success. With HOCA Oil Tools, elevate your downhole operations with Kickover Tools that set new standards for reliability, efficiency, and accuracy in the oil and gas industry.

Buy

In Stock

Product & Service

New

API

Air Freight

Plug with Equalizing Prong and Valve Sub-Assembly

Downhole Tools![]() Hoca Oil Tools in Zwartemeer

Hoca Oil Tools in Zwartemeer

HOCA Oil Tools: Revolutionizing Downhole Operations with Plug with Equalizing Prong and Valve Sub-Assembly In the dynamic and demanding world of downhole operations within the oil and gas industry, the quest for innovation, efficiency, and safety is relentless. HOCA Oil Tools, a leading provider of specialized downhole slick line tools, meets this challenge head-on with our advanced Plug with Equalizing Prong and Valve Sub-Assembly. This tool is meticulously designed to enhance the functionality and safety of downhole operations, providing a solution that is both versatile and reliable. HOCA’s Plug with Equalizing Prong and Valve Sub-Assembly: Tailored for Optimal Performance Our Plug with Equalizing Prong and Valve Sub-Assembly is engineered for precision and durability, designed to address the complex needs of modern downhole activities. This innovative tool combines the functionality of a plug for secure sealing and isolation with the added advantage of an equalizing prong and valve mechanism. This integration allows for controlled pressure equalization, crucial in preventing potential downhole complications and ensuring the safety of the well and personnel. Experience the Difference with HOCA Oil Tools Choosing HOCA Oil Tools’ Plug with Equalizing Prong and Valve Sub-Assembly means opting for a product that stands at the confluence of innovation, quality, and safety. We are committed to providing solutions that not only meet the current demands of the oil and gas industry but also anticipate future challenges, ensuring our clients are equipped for success. Integrating our advanced plug assembly into your downhole operations signifies a move towards enhanced efficiency, safety, and control. With HOCA Oil Tools, you gain more than just a supplier; you gain a partner dedicated to supporting your operational goals with cutting-edge solutions and comprehensive service. Select HOCA Oil Tools for your downhole needs and leverage the advantages of our Plug with Equalizing Prong and Valve Sub-Assembly to optimize your operational outcomes. Partner with us and step into a new era of downhole operations, where efficiency, safety, and performance are paramount. With HOCA Oil Tools, empower your downhole activities with tools that redefine industry standards and drive your success in the competitive oil and gas landscape.

Buy

In Stock

Product & Service

New

API

Air Freight

![]() Hoca Oil Tools in Zwartemeer

Hoca Oil Tools in Zwartemeer

Unlock Enhanced Efficiency and Safety with HOCA Oil Tools' Tubing Mandrel Running Tools In the challenging arena of oil and gas extraction, the significance of reliable, efficient, and precise tools is undeniable. HOCA Oil Tools, renowned for its commitment to innovation and quality, introduces its Tubing Mandrel Running Tools, designed to streamline and secure downhole operations. Our products stand as a testament to our dedication to advancing the oilfield industry's capabilities, offering unparalleled solutions to common downhole challenges. HOCA’s Tubing Mandrel Running Tools: Precision Engineered for Superior Performance HOCA Oil Tools’ Tubing Mandrel Running Tools are meticulously crafted to ensure the safe, efficient, and precise deployment of tubing mandrels within the wellbore. These tools are vital for maintaining the integrity and functionality of the tubing string, playing a crucial role in various downhole operations from completion to intervention. Built from high-grade materials and engineered to withstand demanding downhole conditions, our Tubing Mandrel Running Tools represent the pinnacle of downhole innovation. Experience the HOCA Oil Tools Advantage At HOCA Oil Tools, we understand the complexities of downhole operations and the importance of reliable tools in achieving successful outcomes. Our Tubing Mandrel Running Tools are a reflection of this understanding, offering solutions that enhance efficiency, safety, and cost-effectiveness. Incorporating our Tubing Mandrel Running Tools into your downhole operations not only signifies a commitment to operational excellence but also aligns your projects with the industry's highest standards. With HOCA Oil Tools, you gain more than just a supplier; you gain a dedicated partner committed to your success. Choose HOCA Oil Tools for your Tubing Mandrel Running Tools and experience the difference that quality, innovation, and dedicated support can make in your downhole operations. Elevate your wellbore activities with HOCA Oil Tools – where technology meets tradition in the pursuit of downhole excellence.

Buy

In Stock

Product & Service

New

API

Air Freight

Slickline Swabbing Mandrel Assembly

Downhole Tools![]() Hoca Oil Tools in Zwartemeer

Hoca Oil Tools in Zwartemeer

Optimize Your Well Performance with HOCA Oil Tools' Swabbing Mandrel Assembly In the specialized field of downhole operations within the oil and gas industry, the demand for high-quality, efficient, and reliable tools has never been higher. At HOCA Oil Tools, we stand at the forefront of downhole innovation, providing our clients with advanced solutions designed to optimize well performance and enhance operational efficiency. One such innovation is our Swabbing Mandrel Assembly, a key component in maintaining well pressure and fluid levels. Introducing HOCA's Swabbing Mandrel Assembly: Precision and Efficiency Downhole The HOCA Swabbing Mandrel Assembly is engineered for optimal performance in fluid lifting and wellbore cleaning operations. Designed with the end-user in mind, our Swabbing Mandrels are built from high-grade materials to withstand the rigors of the downhole environment, ensuring durability and long-term service. Compatible with a variety of tubing sizes, our assemblies are tailored to meet the specific requirements of your well operations. Elevating Downhole Operations with HOCA Oil Tools At HOCA Oil Tools, we are committed to advancing the capabilities of the oil and gas industry through our innovative downhole solutions. Our Swabbing Mandrel Assembly is a testament to this commitment, offering a blend of precision, efficiency, and reliability that sets new standards for well performance and maintenance. Integrating HOCA’s Swabbing Mandrel Assembly into your downhole operations means investing in the future of your wells. Not only do our tools enhance operational efficiency, but they also contribute to the overall safety and sustainability of your operations. With HOCA, you're not just purchasing a tool; you're acquiring a partner in downhole success. Unlock the full potential of your downhole operations with HOCA Oil Tools. Experience unparalleled performance, efficiency, and reliability with our Swabbing Mandrel Assembly, and take the first step towards optimized well performance and operational excellence. Choose HOCA Oil Tools for your downhole needs and join the ranks of satisfied clients who have experienced the difference our solutions can make. Elevate your operations with the precision and quality of HOCA’s downhole solutions – where excellence meets innovation.

Buy

In Stock

Product & Service

New

API

Air Freight

![]() Hoca Oil Tools in Zwartemeer

Hoca Oil Tools in Zwartemeer

Transform Your Perforation Operations with HOCA Oil Tools' Mechanical Tubing Perforator In the competitive landscape of the oil and gas industry, achieving precise, efficient, and cost-effective downhole operations is crucial. At HOCA Oil Tools, we understand these challenges and are committed to providing state-of-the-art solutions. Our Mechanical Tubing Perforator stands out as a pinnacle of innovation, specifically designed to enhance the efficiency and accuracy of perforation operations. HOCA’s Mechanical Tubing Perforator: Engineering Precision for Downhole Success The Mechanical Tubing Perforator by HOCA Oil Tools is meticulously engineered to provide precise and efficient perforations in tubing, essential for effective production and injection operations. Crafted from robust materials and designed to withstand harsh downhole environments, our Mechanical Tubing Perforator ensures optimal performance and reliability, delivering clean, precise perforations that enhance fluid communication and well productivity. Experience the HOCA Advantage in Downhole Perforation At HOCA Oil Tools, we pride ourselves on advancing the field of downhole operations with innovative, reliable, and cost-effective solutions. Our Mechanical Tubing Perforator is a testament to this commitment, offering a level of precision, efficiency, and safety that sets new industry standards. Incorporating the HOCA Mechanical Tubing Perforator into your downhole operations signifies a move towards enhanced operational efficiency, safety, and cost-effectiveness. With HOCA Oil Tools, you not only acquire a tool; you gain a strategic partner dedicated to supporting your operational success with leading-edge solutions and comprehensive service. Choose HOCA Oil Tools' Mechanical Tubing Perforator for your downhole needs and join the ranks of industry leaders who trust our products to enhance their operations. Elevate your downhole operations with HOCA Oil Tools – where innovation, precision, and efficiency drive everything we do.

Buy

In Stock

Product & Service

New

API

Air Freight

Knuckle Joint for Wireline Toolstring

Knuckle Joint![]() Hoca Oil Tools in Zwartemeer

Hoca Oil Tools in Zwartemeer

Enhancing Wireline Flexibility with HOCA Oil Tools B.V.'s Advanced Knuckle Joints In the demanding environments of oil and gas extraction, the adaptability and precision of downhole tools are paramount. At HOCA Oil Tools B.V., we specialize in providing state-of-the-art wireline solutions, including our wide range of Knuckle Joints, known for their exceptional flexibility and reliability. Our Knuckle Joints are designed to provide pivotal flexibility in the Wireline Tool String, facilitating angular movement between the tool string and the running or pulling tool, an essential feature for navigating complex downhole geometries. Six Key Benefits of HOCA's Wireline Knuckle Joints: Enhanced Flexibility: Our Knuckle Joints allow for angular movement, enabling the Wireline Tool String to navigate through deviated wellbores efficiently. Improved Tool Placement: By enabling better maneuverability, our Knuckle Joints facilitate precise tool placement, improving the success rates of downhole operations. Increased Operational Range: The added flexibility extends the operational range of wireline tools, allowing for more complex and challenging interventions. Robust Design: Constructed with high-quality materials, our Knuckle Joints withstand harsh downhole environments, ensuring longevity and reliability. Versatile Application: Suitable for a variety of downhole activities, our Knuckle Joints are essential for both standard operations and complex well interventions. Easy Integration: Available with both Threaded and QLS Connections, our Knuckle Joints seamlessly integrate into existing tool strings, enhancing operational efficiency. HOCA's Diverse Array of Wireline Knuckle Joints: Type ‘AO’ Knuckle Joints (Threaded Connection): These are available in sizes from 3/8” to 2 1/2”, designed for easy integration with various tool strings. They offer exceptional flexibility and strength, with sizes accommodating different operational needs, ensuring that tools can navigate wellbore paths effectively. Type ‘AD’ Knuckle Joints (QLS Connection): Catering to advanced operational requirements, these Knuckle Joints provide the same high-level flexibility with quick lock-and-seal connections for faster deployment and retrieval, available in sizes ranging from 1 1/2” to 2 1/2”. Rebco Type ‘AS’ Knuckle Joint (RQLS Connection): An addition to our lineup, offering enhanced swivel action and compatibility with a range of wireline tools, facilitating seamless downhole operations. Each of our Knuckle Joints is engineered with precision, incorporating features such as double fishing necks for increased adaptability and operational safety. The diverse sizes and connection types we offer ensure that there is a HOCA Knuckle Joint suitable for every downhole challenge. By choosing HOCA Oil Tools B.V. for your wireline operational needs, you are selecting a partner dedicated to innovation, quality, and customer service. Our Knuckle Joints represent just one aspect of our commitment to providing the oil and gas industry with tools that meet the highest standards of performance, reliability, and safety. Embrace the flexibility and efficiency of HOCA’s Wireline Knuckle Joints to enhance your downhole operations. Contact us today to learn more about how our tools can transform your well interventions and streamline your operational workflows

Buy

In Stock

Product & Service

New

API

Air Freight

![]() Hoca Oil Tools in Zwartemeer

Hoca Oil Tools in Zwartemeer

Elevate Downhole Cleanliness and Efficiency with HOCA Oil Tools' Junk Basket - Valve Catcher In the dynamic world of oil and gas extraction, maintaining a clean and functional wellbore is crucial for optimal operation and productivity. HOCA Oil Tools, as a specialist in downhole slick line tools, introduces the Junk Basket - Valve Catcher, an indispensable tool designed to enhance the integrity and efficiency of downhole operations. This innovative tool is specifically engineered to capture debris, ensuring your wellbore remains clear and operational. HOCA's Junk Basket - Valve Catcher: Your Solution to Downhole Debris Management The HOCA Junk Basket - Valve Catcher is meticulously crafted to provide a robust solution for capturing and removing all forms of downhole junk, including sand, perforation debris, and broken hardware. Its unique design allows for effective debris retrieval without hindering valve operations, making it an essential tool for maintaining well integrity. Constructed with high-grade materials, our Junk Basket - Valve Catcher withstands the harsh downhole environment, ensuring durability and reliability. Experience the Difference with HOCA Oil Tools At HOCA Oil Tools, we are committed to advancing the field of downhole operations with innovative, high-quality tools that address the specific challenges faced by the oil and gas industry. Our Junk Basket - Valve Catcher is a prime example of this commitment, offering a practical, effective solution for maintaining wellbore cleanliness and functionality. Incorporating the HOCA Junk Basket - Valve Catcher into your downhole operations signifies a step toward enhanced efficiency, safety, and cost-effectiveness. With HOCA Oil Tools, you not only acquire a tool; you gain a partner dedicated to your success in the challenging world of oil and gas extraction. Choose HOCA Oil Tools for your downhole needs and join the ranks of industry professionals who trust our Junk Basket - Valve Catcher to keep their operations running smoothly and efficiently. Partner with HOCA and transform your downhole challenges into successes.

Buy

In Stock

Product & Service

New

API

Air Freight

![]() Hoca Oil Tools in Zwartemeer

Hoca Oil Tools in Zwartemeer

Achieve Superior Wellbore Cleanliness with HOCA Oil Tools' Wire Brush In the demanding realm of oil and gas extraction, the cleanliness and integrity of wellbores are paramount for operational success. Recognizing this critical need, HOCA Oil Tools has developed a premier solution: the Wire Brush, an essential component of our comprehensive downhole slick line tools portfolio. Designed to tackle the toughest wellbore contaminants, our Wire Brush is engineered for excellence, ensuring your operations maintain peak efficiency and safety. HOCA's Wire Brush: Pioneering Downhole Cleanliness At HOCA Oil Tools, we understand that every downhole environment poses unique challenges. That's why our Wire Brush is meticulously crafted to remove deposits, scale, and other obstructions with unmatched efficiency. Constructed from durable materials capable of withstanding harsh downhole conditions, the HOCA Wire Brush is your ally in maintaining wellbore integrity and optimizing production flow. Elevating Downhole Maintenance with HOCA Oil Tools Innovation, quality, and customer satisfaction are at the core of HOCA Oil Tools' mission. Our Wire Brush exemplifies these values, providing a solution that not only meets but exceeds the demands of modern downhole operations. With the HOCA Wire Brush, operators can expect a level of cleanliness and efficiency that sets new industry standards. Adopting the HOCA Wire Brush into your downhole cleaning regimen is an investment in your operation's future. It signifies a commitment to operational excellence, safety, and cost-effectiveness. Our dedicated team at HOCA Oil Tools is committed to supporting your success by providing superior downhole solutions that address the specific challenges of the oil and gas industry. Embrace the future of downhole maintenance with HOCA Oil Tools’ Wire Brush – your solution for maintaining pristine wellbores and maximizing operational outcomes. Experience the difference that comes with using tools crafted for excellence and backed by an unwavering commitment to your operational success. Choose HOCA Oil Tools for your downhole needs and join the ranks of industry professionals who trust our Wire Brush to keep their operations running smoothly, safely, and efficiently.

Buy

In Stock

Product & Service

New

API

Air Freight

![]() Hoca Oil Tools in Zwartemeer

Hoca Oil Tools in Zwartemeer

Elevating Downhole Precision: HOCA Oil Tools B.V.'s Slickline Stem Solutions In the intricate arena of oil and gas extraction, downhole operations necessitate tools that promise not only precision but also unwavering reliability. HOCA Oil Tools B.V. takes pride in offering a sophisticated range of slickline stems that cater to a myriad of operational needs, ensuring unmatched performance and safety. Our expertise in crafting these essential tools is evident from the wide array of slickline stems available, designed to enhance the efficiency and safety of wireline operations. Benefits of Using HOCA's Slickline Stems: Enhanced Downhole Control: Our stems provide the necessary weight to ensure smooth and controlled movements of the tool string within the wellbore, enhancing operational precision. Versatility for Various Applications: From standard solid bars to specialized options like lead or tungsten filled, our range caters to different well conditions and requirements. Optimized Performance: The added weight helps counteract wellbore pressure, improving the impact and effectiveness of downhole tools, particularly in jarring operations. Increased Safety: Proper use of slickline stems reduces the risk of wireline snapping and other operational hazards, ensuring a safer environment for field personnel. Durability in Harsh Conditions: Manufactured with high-quality materials, our stems are designed to withstand the demanding conditions of downhole environments. Customization Options: Available in various sizes and materials, our stems can be tailored to meet the specific needs of each operation, ensuring maximum efficiency and effectiveness. Main Features of HOCA's Slickline Stems: Type ‘A’ Stem (Weight Bar): Offers solid bar configurations ideal for standard operations, providing necessary weight to the tool string with threaded connections for easy integration. Type ‘BO’ Lead Filled Stem: Incorporates lead within the stem to add substantial weight, ideal for deeper or more challenging well conditions, ensuring better control and impact. Type ‘EO’ Roller Stem: Features external rollers to minimize friction and wear during operations, enhancing the stem's longevity and performance in deviated wells. Type ‘ED’ Tungsten Filled Stem: Utilizes tungsten to provide maximum weight in a minimal space, perfect for high-pressure wells where additional downforce is required. Customization and Variety: Our stems are available in various lengths, diameters, and thread connections, ensuring compatibility with different tool strings and operational needs. HOCA Oil Tools B.V.'s commitment to quality and innovation is reflected in our slickline stem offerings. By providing a comprehensive range of sizes, materials, and types, we ensure that our clients have access to the tools necessary for their unique downhole challenges. Trust HOCA for your downhole tool needs, where precision meets durability.

Buy

In Stock

Product & Service

New

API

Air Freight

Circulating Type Chokes for Nipples

Downhole Tools![]() Hoca Oil Tools in Zwartemeer

Hoca Oil Tools in Zwartemeer

HOCA Oil Tools: Mastering Flow Control with Circulating Type Chokes for Nipples In the specialized field of downhole operations, mastering the control of fluid flow within the wellbore is critical for operational success and efficiency. HOCA Oil Tools is at the forefront of this challenge, offering advanced solutions with our Circulating Type Chokes for Nipples. Designed to integrate seamlessly with landing nipples in the wellbore, these tools are essential for precise flow control and well management during various downhole activities. HOCA’s Circulating Type Chokes for Nipples: Precision Engineered for Optimal Flow Control Our Circulating Type Chokes for Nipples are designed for operators seeking to maintain precise control over fluid flow in their downhole operations. Whether for circulation, testing, or intervention tasks, our chokes provide the versatility and reliability needed in today’s diverse well environments. Constructed with the highest quality materials and engineered to withstand harsh downhole conditions, HOCA’s chokes ensure optimal performance and durability. Experience the HOCA Oil Tools Difference Choosing HOCA Oil Tools’ Circulating Type Chokes for Nipples means opting for a solution that embodies innovation, quality, and operational excellence. Our commitment to providing cutting-edge downhole solutions ensures that our products meet the complex demands of modern oil and gas operations, delivering performance that exceeds expectations. Incorporating our Circulating Type Chokes into your downhole toolkit signifies a step toward enhanced operational control, efficiency, and safety. With HOCA Oil Tools, you gain not just a supplier but a dedicated partner committed to supporting your downhole challenges with advanced solutions and expert service. Opt for HOCA Oil Tools for your downhole needs and unlock the full potential of your operations with our Circulating Type Chokes for Nipples. Partner with us, and elevate your downhole flow control to new levels of precision and reliability. With HOCA Oil Tools, enhance your downhole operations with tools that redefine efficiency, safety, and performance in the demanding oil and gas industry.

Buy

In Stock

Product & Service

New

API

Air Freight

![]() Hoca Oil Tools in Zwartemeer

Hoca Oil Tools in Zwartemeer

Unlocking Efficiency in Downhole Operations: HOCA Oil Tools B.V.'s Advanced Slickline Swivel Joints In the dynamic landscape of downhole operations, the role of slickline swivel joints becomes pivotal in ensuring seamless, efficient, and safe wireline operations. HOCA Oil Tools B.V., a renowned name in the oil and gas industry, stands at the forefront of delivering cutting-edge slickline solutions. Our array of slickline swivel joints is designed to meet and exceed the operational demands and challenges faced by our clients. Pioneering Slickline Swivel Joints: HOCA Oil Tools B.V. offers an extensive range of slickline swivel joints, including the Type ‘HO’ and ‘HD’ swivel joints, engineered to minimize wireline twisting during downhole operations. This not only enhances safety but also improves operational efficiency by reducing the risk of wireline entanglement and breakage. Key Benefits of Our Slickline Swivel Joints: Reduced Wireline Twisting: Our swivel joints significantly reduce the twisting of wireline, thus minimizing the risk of operational downtime and wire breakage. Enhanced Operational Safety: By preventing wireline kinks and twists, our swivel joints contribute to safer downhole operations, protecting both personnel and equipment. Increased Efficiency: Smooth wireline operations ensure quicker job completion and reduced non-productive time. Durability and Reliability: Made from high-grade materials, our swivel joints withstand harsh downhole conditions, ensuring long service life and reliability. Versatility: Available in various sizes and configurations, our swivel joints cater to a wide range of downhole requirements and wireline types. Ease of Integration: Designed for easy integration into existing tool strings, our swivel joints facilitate seamless operations without the need for extensive modifications. Main Features of HOCA's Slickline Swivel Joints: Type ‘HO’ Swivel Joint: Designed to minimize wireline twisting, available in sizes from 1” to 2 1/2", with threaded connections for easy installation. These swivel joints feature top sub, pin, ball connector, ball sub, and bottom sub components, ensuring robust performance and ease of maintenance. Type ‘HD’ Swivel Joint: Similar to the Type ‘HO’ but designed for even more demanding environments, with ‘QLS’ - ‘RQLD’ connections, providing additional strength and durability. These swivel joints are also available in sizes from 1 1/2” to 2 1/2", tailored for heavy-duty operations. At HOCA Oil Tools B.V., we understand the complexities of downhole operations. Our slickline swivel joints are a testament to our commitment to innovation, safety, and efficiency. Embrace the future of wireline operations with HOCA, where performance meets reliability. Contact us today to learn more about how our slickline solutions can optimize your operations.

Buy

In Stock

Product & Service

New

API

Air Freight

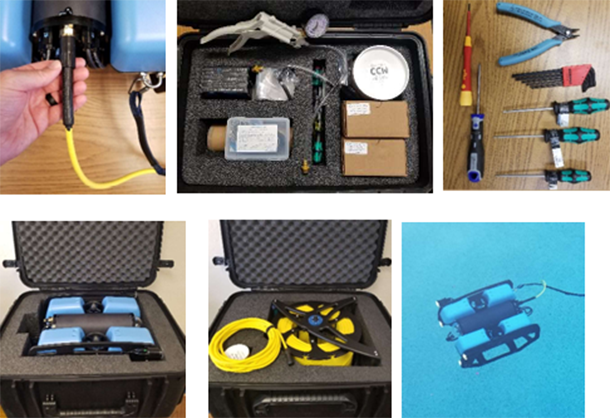

Revolutionize Cementing and Acidizing Operations with HOCA Oil Tools' Dump Bailers In the dynamic and challenging environment of downhole operations, the need for precise, efficient, and reliable tools has never been greater. HOCA Oil Tools, a pioneer in downhole slick line technology, is at the forefront of this demand with its state-of-the-art Dump Bailers. Specifically designed for targeted applications such as cementing and acidizing, these tools play a pivotal role in enhancing well integrity and performance. HOCA Dump Bailers: Precision in Every Drop Our Dump Bailers are engineered to deliver materials like cement, acids, or other substances directly to the required downhole location with utmost precision. Constructed from durable materials resistant to harsh chemicals and high pressures, HOCA's Dump Bailers ensure that even the most demanding downhole conditions can be tackled with confidence and control. Elevate Your Downhole Operations with HOCA Oil Tools At HOCA Oil Tools, we understand the complexities and demands of modern oil and gas extraction. Our Dump Bailers are designed with this understanding at their core, providing innovative solutions that address the specific needs of downhole operations. By integrating our tools into your operations, you gain access to a level of precision, efficiency, and reliability that sets new industry standards. Invest in HOCA's Dump Bailers to leverage their benefits in your downhole operations. Whether you are executing precise cement plugs, combating downhole leaks, or enhancing production through acidization, our tools provide the solutions you need to achieve optimal results. Discover the difference that HOCA Oil Tools can make in your downhole operations. With our commitment to quality, innovation, and customer service, we provide not just tools, but comprehensive downhole solutions that drive your success. Join the ranks of satisfied clients who have experienced the transformative impact of HOCA’s Dump Bailers in their operations. Choose HOCA Oil Tools for unparalleled downhole solutions that elevate your operational efficiency, safety, and success.

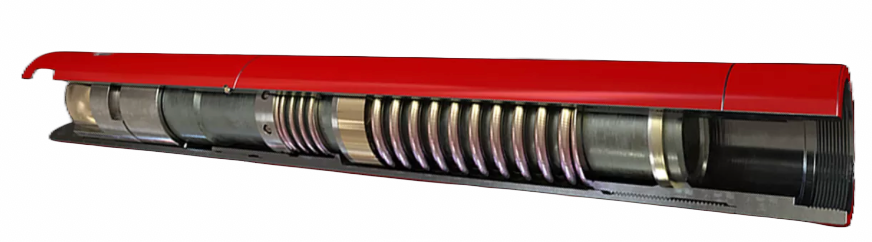

Rod Pump of various diameters and stroke lengths to optimize oil production

Rod Pump![]() Midastream Supply Company in Airdrie

Midastream Supply Company in Airdrie

Sucker rod pumping systems are the oldest and most widely used type of artificial lifting system for oil wells. Sucker-rod pumping is the most widely used artificial lift method for onshore oil wells. Sucker-rod strings transfer the motion from the driving machine on the wellhead to the downhole oil pump. Pump diagnoses are generally conducted through an interpretation of the pump dynamometer graph (pump card).

Buy

Made to Order

Product

New

API

Sea Freight

![]() CWB National Leasing in Winnipeg

CWB National Leasing in Winnipeg

Enhance Your Presentations with Projector Leasing from CWB National Leasing Elevating Your Business Communications with High-Quality Visual Solutions In a business environment where presentations and meetings are integral, having access to top-quality projectors can significantly impact the effectiveness of your communications. Leasing projectors through Canadian Western Bank (CWB) National Leasing offers a flexible, cost-effective, and efficient solution for businesses seeking to upgrade their visual presentation capabilities. Here’s how leasing projectors can benefit your business: 1. Quick Access to Advanced Projector Technology CWB National Leasing understands the importance of high-quality visual aids in business settings. They offer a speedy leasing process, typically making decisions within 48 hours of application submission. This rapid service ensures that your projectors can be delivered and set up quickly, enhancing your presentation capabilities without delay. 2. Increased Financial Flexibility Leasing projectors with CWB National Leasing enhances your financial power. It allows you to free up capital by opting for manageable periodic payments over a significant upfront purchase. The option to add extra features or accessories to your projectors for a small payment increase allows for customization to meet specific presentation needs. 3. Effective Cash Flow Management Manageable lease payments over the term mean your projectors start contributing to your business’s effectiveness while being paid off. This strategy helps maintain a balanced expense-to-revenue ratio, which is essential for business growth and financial stability. 4. Customizable Payment Plans CWB National Leasing offers a variety of payment options, including seasonal, semi-annual, or annual plans, tailored to your business’s financial cycle. This flexibility is particularly beneficial for businesses with variable income, ensuring that payments are practical and fit your financial situation. 5. Potential Tax Benefits Leasing projectors can offer tax advantages, such as the ability to expense lease payments instead of capitalizing the cost of the equipment. Consulting with a tax advisor is advisable to understand how leasing can optimize your business’s tax position. Conclusion Choosing to lease projectors through CWB National Leasing is a strategic decision that equips your business with essential presentation tools while maintaining financial flexibility. It ensures access to the latest projector technology, vital for delivering high-quality, impactful presentations, without the financial burden of a large upfront investment. This leasing approach enables enhanced communication effectiveness, improved audience engagement, and increased productivity, contributing significantly to the success and growth of your business in today’s competitive market.

Service

In Stock

Service

New

ISO

![]() Lovat Gas Solutions in Edmonton

Lovat Gas Solutions in Edmonton

Maximize the Value of Your Stranded Gas with Lovat Gas Solutions Stranded gas, trapped in wells that are isolated from pipeline infrastructure, represents an untapped opportunity for producers. At Lovat Gas Solutions, we specialize in helping companies unlock the value of their stranded gas assets. If you have idle gas wells and are seeking to realize the potential value of this resource, we are here to assist you in developing a production and revenue plan. Stranded gas wells can present unique challenges, but they also hold significant potential. To extract value from these assets, a well-designed plan is essential. Our team of experts at Lovat Gas Solutions has the knowledge and experience to help you navigate this process and develop a comprehensive production and revenue plan for your stranded gas. Why choose Lovat Gas Solutions for your stranded gas needs? 1. Specialized Expertise: We understand the complexities and nuances of stranded gas projects. With our specialized expertise, we can assess the unique characteristics of your stranded wells and design a customized plan to extract and monetize the gas effectively. 2. Value Optimization: Our goal is to help you maximize the value of your stranded gas assets. By developing a production and revenue plan tailored to your specific situation, we aim to unlock the full potential of your resources and generate a significant return on investment. 3. Comprehensive Support: From the initial evaluation to the execution of the plan, Lovat Gas Solutions provides end-to-end support. Our team will collaborate closely with you, offering guidance and assistance at every stage of the process to ensure a seamless and successful outcome. 4. Sustainable Approach: We prioritize environmental sustainability in all our operations. Our plans for stranded gas production are designed to comply with regulatory standards and minimize any potential impact on the environment. We are committed to helping you extract value from your stranded gas assets while maintaining responsible and sustainable practices. Take the first step towards unlocking the value of your stranded gas assets. Contact Lovat Gas Solutions today, and let our team of experts develop a production and revenue plan that suits your specific needs. With our specialized expertise, comprehensive support, and commitment to sustainability, we are the partner you can rely on to maximize the potential of your stranded gas resources. Trust Lovat Gas Solutions to transform your idle gas assets into valuable sources of revenue.

Service

Made to Order

Product & Service

New

ANSI

Land Freight

![]() Canaweld Inc. in Vaughan

Canaweld Inc. in Vaughan

Experience Precision and Professionalism with the TIG DC 202 Pulse-D Welding Machine At Canaweld, we understand the importance of precision and sleek design in welding, especially for industries like oil and gas, marine, aerospace, and medical. That's why we offer a wide range of TIG welders designed to give you the control necessary to achieve professional results with various parent metals. Our TIG welders are the ultimate choice for welders who demand excellence and quality in their work. Introducing the TIG DC 202 Pulse-D - Your Portable Powerhouse The TIG DC 202 Pulse-D is a welding machine that sets new standards in the industry. Portable, powerful, and versatile, it is the perfect tool for welders seeking exceptional TIG welds on stainless and mild steel or Stick welding. The professional pulse features, combined with HF start, make it an ideal companion for achieving high-quality welds, even on very thin steel, with no distortion. Unmatched Features for Unrivaled Performance At Canaweld, we believe in delivering welding machines that exceed expectations. The TIG DC 202 Pulse-D is packed with features that enhance your welding experience: • High Frequency (HF) for start, ensuring a smooth and efficient start to your welding projects. • Rigorously tested in (104°F/40°C) to guarantee optimal performance even in the toughest conditions. • Digital control of all welding parameters, giving you precise control over your welding process. • Dual control options: Amperage control accessible by both foot pedal and fingertip controls on the torch body, offering convenience and flexibility during welding. • Pulse TIG welding for better arc control and reduced workpiece deformation, resulting in professional welds on thin materials. • Exceptional welding characteristics in Stick mode with the most common rod in the market, adding versatility to your welding tasks. • Long-distance welding capability: Ability to use up to 165 feet (50 meters) leads without any power loss at the welding circuit, giving you freedom of movement on the job. • Digital adjustment of pre-gas, base current, welding current, slope up, pulse parameters, slope down, and post-gas with digital display for precise customization. • Arc Force automatically selects the best welding arc dynamics, optimizing your welding performance. • Visual welding current pre-setting ability for accurate and efficient parameter selection. • Fan cooled and thermally protected against overheating, ensuring durability and safety during operation. • Durable metal face panel, guaranteeing longevity and protection. • Generator compatible, providing versatility and adaptability for various worksites. Your Welding Excellence is Our Priority We take pride in our products, and the TIG DC 202 Pulse-D is no exception. To ensure your satisfaction and confidence in our welding machine, we offer a comprehensive 3-year warranty, protecting your investment and giving you peace of mind. Elevate Your Welding Experience with Canaweld Take control of your welding projects with precision and professionalism. Choose the TIG DC 202 Pulse-D from Canaweld and experience welding excellence like never before. Whether you're in the marine, aerospace, or medical industry, or any other field that demands top-tier welds, this welding machine will deliver unparalleled performance and superior results. Invest in the future of welding technology. Choose Canaweld, and unlock your welding potential with the TIG DC 202 Pulse-D. Experience precision, power, and professionalism in every weld.

Buy

In Stock

Manufacturer

New

ASME

Land Freight

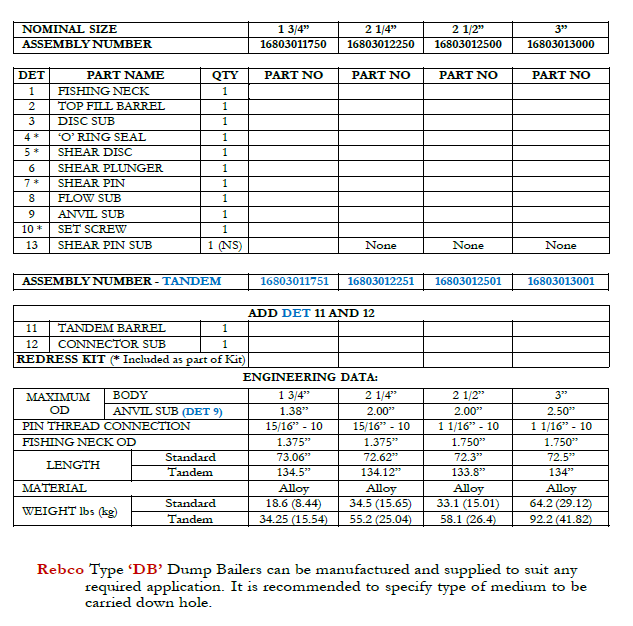

![]() Poseidon Robotics in Chandler

Poseidon Robotics in Chandler

Dive into the Depths: Enhance Your ROV Skills with Poseidon Robotics' ROV Field Training As the underwater frontier beckons with mysteries and challenges, subsea robotics is at the forefront of exploring and unraveling its secrets. At Poseidon Robotics, we believe that knowledge and skill are the cornerstones of successful ROV (Remotely Operated Vehicle) operations. That's why we are proud to present our comprehensive ROV Field Training program, designed to equip you with the expertise to navigate the depths with confidence. Unparalleled Hands-On Experience Our ROV Field Training is a unique opportunity to gain hands-on experience in operating and maneuvering advanced underwater robotics. Under the guidance of our seasoned instructors, you will immerse yourself in the world of subsea exploration, learning practical skills that will empower you to conduct successful missions and overcome real-world challenges. Tailored for All Skill Levels Whether you're a seasoned ROV pilot or just embarking on your subsea robotics journey, our training program caters to all skill levels. Beginners will receive comprehensive instruction on ROV basics, including vehicle setup, navigation, and troubleshooting. Experienced operators will have the chance to refine their skills, learn advanced techniques, and master specialized maneuvers. Customized Training for Your Needs At Poseidon Robotics, we understand that each organization and project is unique. That's why we offer customized training programs tailored to your specific needs. Our team will work closely with you to identify your goals and objectives, ensuring that the training aligns with your requirements. Whether you're in the oil and gas industry, marine research, or environmental conservation, our training program will be adapted to suit your field. In-Depth Learning Modules Our ROV Field Training covers a wide range of critical topics, including: 1. ROV Operation Fundamentals: Understanding the vehicle components, controllers, and communication systems. 2. Navigation and Maneuvering: Mastering piloting techniques, maintaining stability, and performing complex maneuvers. 3. Mission Planning and Execution: Developing effective mission plans and strategies for successful outcomes. 4. Troubleshooting and Maintenance: Learning to identify and address common technical issues to ensure seamless operations. 5. Safety and Risk Management: Understanding safety protocols, emergency procedures, and risk assessment. Empowering Your Team for Success By participating in Poseidon Robotics' ROV Field Training, you are investing in the success of your team and your subsea operations. Our mission is to empower professionals like you with the knowledge and skills needed to unlock the full potential of underwater exploration and achieve remarkable results. Join Poseidon Robotics' ROV Field Training Today Don't miss this opportunity to take your ROV expertise to new heights. Reach out to us today to learn more about our training program and how it can elevate your subsea capabilities. Dive into the depths with confidence, precision, and efficiency, guided by Poseidon Robotics' unwavering commitment to excellence in subsea robotics training.

Service

Made to Order

Service

New

ASME

Air Freight

![]() Hoca Oil Tools in Zwartemeer

Hoca Oil Tools in Zwartemeer

Unlocking Efficiency with HOCA Oil Tools B.V.'s Advanced Slickline Blind Boxes In the complex world of oilfield services, particularly within the realm of slickline operations, the versatility and precision of downhole tools are of paramount importance. At HOCA Oil Tools B.V., we take pride in our comprehensive range of slickline blind boxes, designed to enhance operational efficiency and safety in the oil and gas industry. Our Type ‘A’ Blind Box series demonstrates our commitment to innovation and quality, catering to a wide range of operational needs. Main Features of HOCA's Slickline Blind Boxes: Diverse Size Range: Available in nominal sizes from .375 inches to 6.687 inches, catering to a broad spectrum of wellbore sizes and wireline operations. High-Quality Materials: Manufactured using robust materials, our blind boxes are designed to withstand the rigors of downhole environments, ensuring reliable performance. Precision Engineering: The precision in crafting each blind box, from threading to length specifications, ensures optimal performance and compatibility with existing slickline tool strings. Customization: Besides standard sizes, we offer custom orders to meet unique operational needs, ensuring that all aspects of the blind box, from thread type to length, are tailored to client specifications. Operational Efficiency: Designed for easy integration and use, our blind boxes help streamline slickline operations, reducing downtime and enhancing overall efficiency. Technical Support: HOCA Oil Tools B.V. provides comprehensive technical support, ensuring that our clients have the guidance needed to select and utilize the most appropriate blind boxes for their operations. At HOCA Oil Tools B.V., we understand the critical nature of slickline operations in the oil and gas industry. Our slickline blind boxes are a testament to our commitment to quality, innovation, and customer service. Choose HOCA for your downhole tool needs and experience the difference that professional-grade tools, backed by industry-leading support and expertise, can make in your operations

Buy

In Stock

Product & Service

New

API

Air Freight

![]() InWaTec Combined in Vechta

InWaTec Combined in Vechta

Enhancing Well Efficiency: InWaTec Combined’s Precision E-line Packer Setting Services The backbone of any well’s structural integrity and operational efficiency lies in the strategic placement and setting of production packers. InWaTec Combined’s E-line Packer Setting Services provide meticulous installation of these critical components, ensuring an optimal seal and isolation within your wellbore. A production packer is not just a piece of hardware; it’s a guardian that ensures the separation of production zones, safeguards the casing from pressure, and enhances the overall management of the well. Our E-line Packer Setting Services cater to both production and service packer requirements, providing versatile solutions tailored to the unique challenges of your well operations. Production Packers: These remain in place during well production, set above the top perforations or sand screens. They are pivotal in multi-zone reservoirs, where they isolate perforations for each zone, allowing for selective production through the use of sliding sleeves. Service Packers: Employed temporarily during well servicing tasks like cement squeezing, acidizing, fracturing, and well testing, service packers are essential for the precise and safe execution of these operations. Packers are designed with a keen eye on reliability—metal slips and rubber elements, or metal rings in high-pressure scenarios, ensure a firm grip and seal against the casing ID. Our E-line Packer Setting Services employ the latest in axial load technology, whether hydraulic, mechanical, or chemical, to expand and secure these packers at the optimal depth. For permanent well configurations, our permanent packers offer a cost-effective and robust solution, boasting superior sealing and gripping capabilities. When retrievability is key, our retrievable packers provide flexibility for secondary recoveries, re-completions, or production tubing changes, with designs that ensure ease of removal and the possibility of reuse after servicing. InWaTec Combined’s commitment to excellence in E-line Packer Setting Services is unwavering. We provide not only the tools but also the strategic foresight and technical support to ensure that your packer installation enhances well performance, maintains integrity, and supports your production goals. Partner with InWaTec Combined for your packer setting needs and experience the assurance that comes from precision, durability, and adaptability. Our services are designed to secure your well’s future, one packer at a time.

Service

In Stock

Service

New

API

Land Freight

MS-32 Multistage Steam Turbine

Back Pressure Turbine![]() Kessels Engineering Works Pvt. Ltd. in New Delhi

Kessels Engineering Works Pvt. Ltd. in New Delhi

Unleash Unprecedented Power with the Kessels MS-102 Multistage Steam Turbine: The Apex of Efficiency and Reliability In the oil and gas industry, where power and precision are non-negotiable, Kessels Steam Turbines proudly presents the MS-102 Multistage Steam Turbine – a true marvel of engineering designed to redefine excellence in the world of steam turbines. Mastering Back-Pressure Turbines Back pressure turbines have long been the cornerstone of industrial steam applications, and our MS-102 Multistage Steam Turbine takes their capabilities to an entirely new level. Available in both single-stage and multi-stage configurations, these turbines are the linchpin between boiler units and process steam headers, revolutionizing steam utilization and power generation. Efficiency Beyond Compare At the heart of the MS-102 Multistage Steam Turbine lies the essence of back pressure turbines – the straight-back pressure design. This innovation ensures the seamless utilization of exhaust steam, aligning perfectly with process demands. Every unit of electrical power generated is consumed precisely as per the process steam demand, marking a new pinnacle of efficiency. Applications Without Boundaries Our MS-102 turbine is not merely a machine; it's a versatile powerhouse ready to excel in an array of applications: Drive Applications: Whether in the oil and gas sector, sugar mills, sugar fibrizor systems, shredder drives, pump drives, or beyond, our turbine delivers power where it's needed most. Power Generation Applications: Embrace sustainability by using our turbine to generate electricity, powering generators with clean and efficient steam energy while reducing your carbon footprint. Bleed Back-Pressure Steam Turbines At Kessels, we understand that adaptability is key. Our MS-102 turbine comes equipped with built-in bleed points, enabling uncontrolled extraction of steam within a medium pressure range. This feature is invaluable when low-volume steam demands and high tolerance for pressure variations are essential. Kessels turbines seamlessly combine the best of both bleed and back-pressure mechanisms. Extraction Back-Pressure Steam Turbines For industries with substantial process steam demand volumes and zero tolerance for pressure variations, our steam turbines with controlled extraction vents come to the forefront. Operating efficiently under intermediate pressure levels, these turbines ensure a consistent and reliable steam supply on which your operations can depend. Why Choose Kessels? Choosing Kessels Steam Turbines is more than a business decision; it's a commitment to a legacy of excellence, innovation, and reliability. Our MS-102 Multistage Steam Turbine is the embodiment of these principles, offering you: Unmatched Efficiency: Maximize steam utilization while minimizing waste, resulting in cost savings and increased productivity. Reliability Beyond Question: Built with precision and rigorously tested to ensure uninterrupted operations, even in the most demanding environments. Unparalleled Versatility: Adapt effortlessly to changing needs, be it for drive applications or eco-friendly power generation, knowing that Kessels has you covered. A Sustainable Tomorrow: Harness the power of steam for electricity generation, reduce your environmental impact, and contribute to a greener future. Expert Support: Our team of specialists is at your service, ready to assist with installation, maintenance, and troubleshooting. Empower Your Future with Kessels In the fiercely competitive world of the oil and gas industry, every advantage matters. Step into a future of efficiency, reliability, and sustainability with the Kessels MS-102 Multistage Steam Turbine. Contact us today to discover how our turbine can revolutionize your operations and lead you toward a future of unprecedented success. Kessels Steam Turbines – Powering Progress, Powering You.

Buy

Made to Order

Manufacturer

New

ISO

Air Freight

WI Water Injection Valve 1.75 inch

Injection Valve![]() Midastream Supply Company in Airdrie

Midastream Supply Company in Airdrie

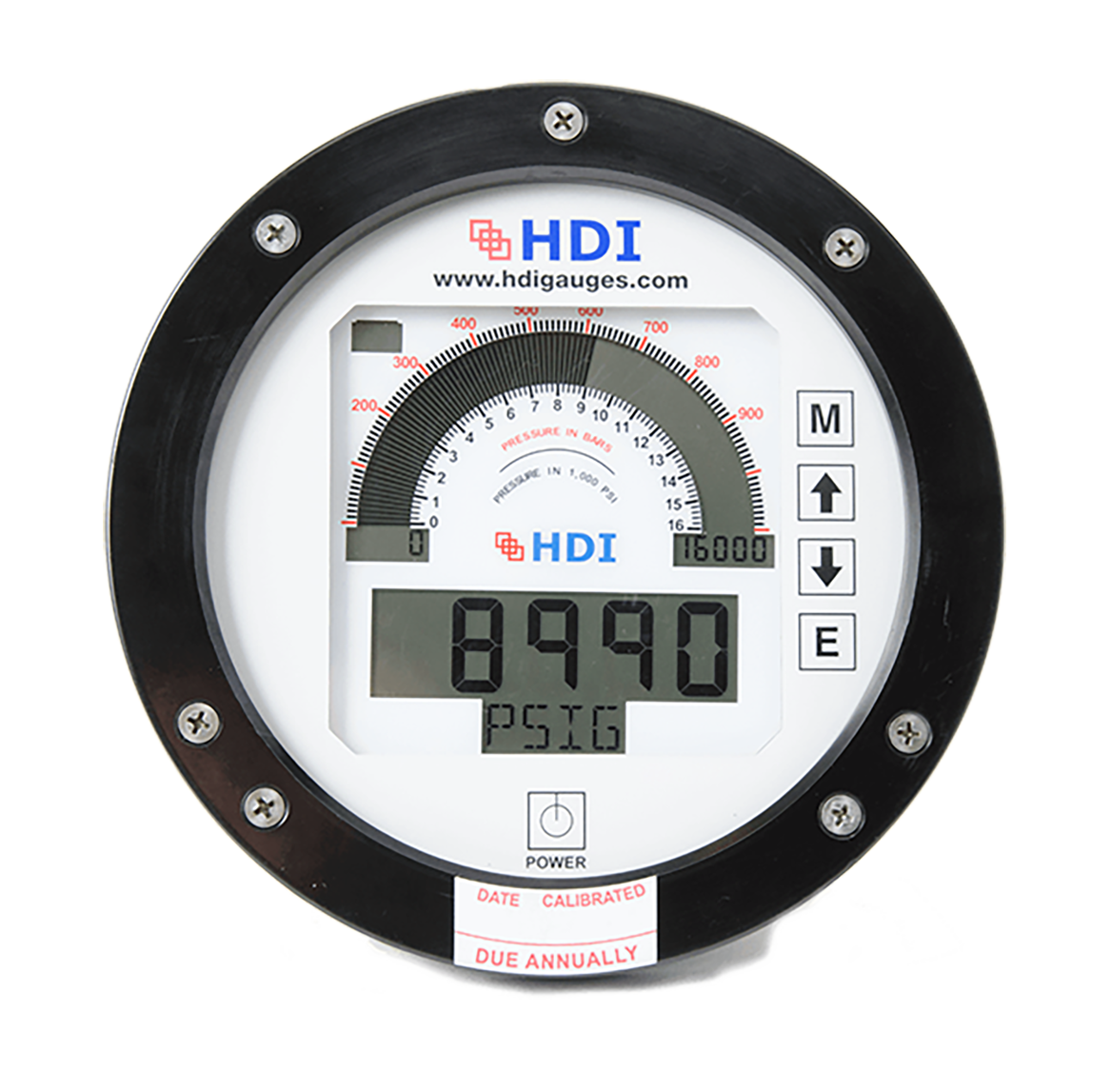

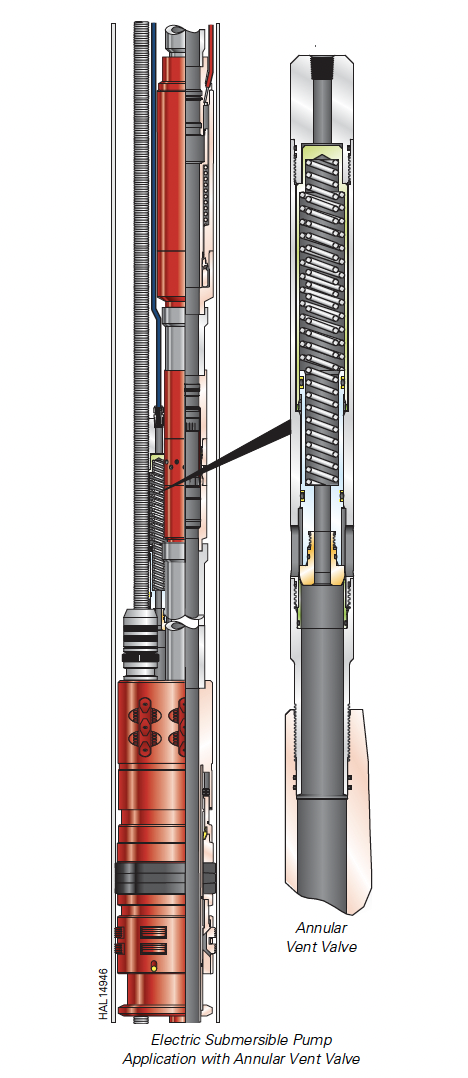

The WI retrievable injection valve is a high-performance, high-flow rate injection valve. High throughput is achieved by a unique valve configuration that minimizes turbulent and potentially erosive flow. Operation is not dependent on a specific flow rate, pressure, or setting depth, thus negating the need for adjustment over time. The valve incorporates a metal-to-metal valve and seat energized by the combination of an integral spring and well pressure acting from below. The WI injection valve can be deployed on a wireline lock or through-tubing pack-off device, providing flexibility not available with alternative injection valve systems. As a result of the simple design with fewer parts, redress and repair costs are considerably lower than those for other injection valve systems. Applications The WI injection valve is primarily used in water injection applications as an alternative to conventional tubing or wireline-set safety valves. The valve is also commonly used as a retrofit solution in water injectors in which a tubing to annulus leak has occurred. The valve can be deployed below the leak point to eliminate uncontrolled annulus pressure increases when the injection stops. Features » Compatible with all known lock systems » Dedicated designs to suit Halliburton EB0 intervention packers » Enhanced internal flow profile » Simple design and construction » Flow-loop testing performed to establish pressure drop versus pump rate *information referenced from supplier catalog.

Buy

Made to Order

Product

New

API

Sea Freight

![]() Poseidon Robotics in Chandler

Poseidon Robotics in Chandler

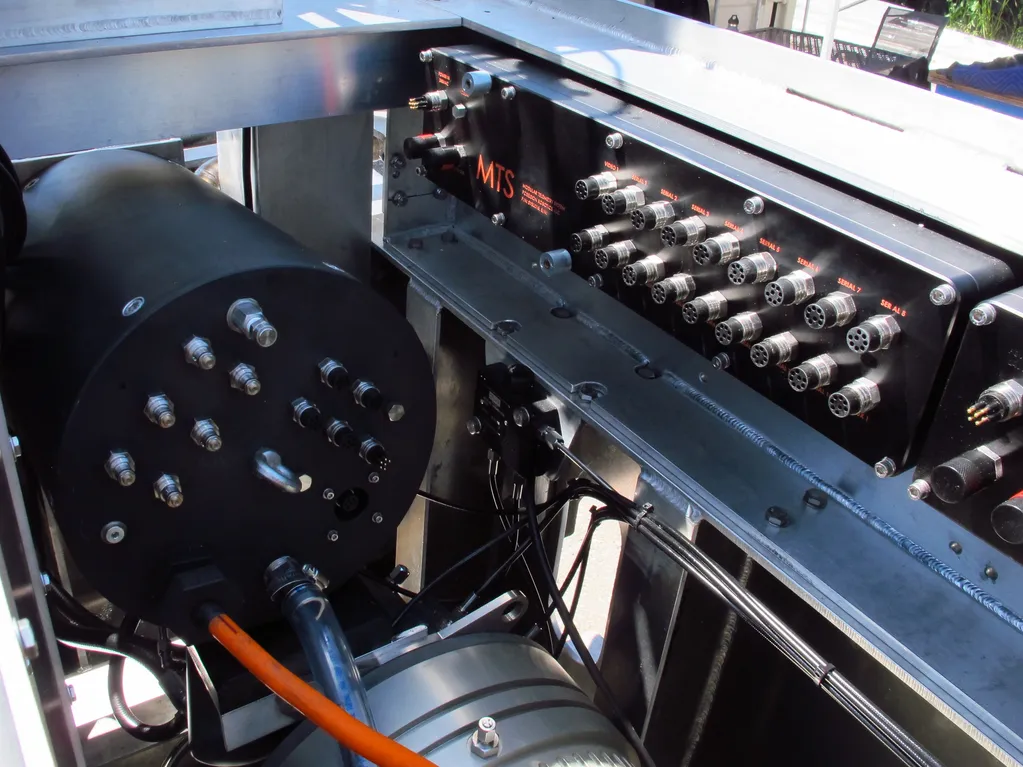

Poseidon Robotics Introduces the Subsea Transformer: Taking Telemetry to New Depths In our unwavering commitment to advancing subsea robotics and ROV technology, Poseidon Robotics is thrilled to introduce our latest breakthrough: the Subsea Transformer. As part of our renowned Modular Telemetry System, this innovative subsea transformer assembly is set to redefine the capabilities of telemetry in deep-water operations. Unlocking New Possibilities At Poseidon Robotics, we understand the unique challenges faced by subsea professionals, and we continuously strive to provide solutions that exceed expectations. The Subsea Transformer is a testament to this dedication, offering a seamless integration of state-of-the-art components to empower your subsea missions. High Voltage Meets High Performance Designed with precision engineering and utilizing cutting-edge technology, our Subsea Transformer boasts a 3kV input and delivers an impressive 240VAC + HV motor output. This combination of high voltage and performance ensures efficient and reliable power distribution for your critical subsea operations. MacArtney Opto-Link Connectors The Subsea Transformer is equipped with MacArtney Opto-Link connectors, renowned for their robustness and reliability. These connectors ensure secure data transmission, minimizing the risk of signal loss and maintaining a seamless flow of information between your subsea equipment and surface systems. CWDM Technology To further optimize data transmission and maximize the potential of your subsea operations, our Subsea Transformer incorporates Coarse Wavelength Division Multiplexing (CWDM) technology. By enabling multiple signals to be transmitted over a single fiber optic cable, CWDM enhances the efficiency of your telemetry system, reducing cable requirements and streamlining your subsea setup. Unparalleled Integration The Subsea Transformer assembly is engineered to seamlessly integrate with our Modular Telemetry System, forming a powerful combination that is greater than the sum of its parts. This integration empowers you with a comprehensive telemetry solution, allowing you to focus on your subsea objectives without the distractions of technical complexities. Reliability and Performance You Can Trust When it comes to subsea operations, reliability is paramount. Poseidon Robotics has meticulously tested and validated the Subsea Transformer to ensure it performs flawlessly even in the harshest subsea environments. With our product, you can trust that your telemetry system will operate at peak performance, unleashing new possibilities for your subsea endeavors. Elevate Your Subsea Missions with Poseidon Robotics Discover a new era of subsea telemetry capabilities with Poseidon Robotics' Subsea Transformer. Whether you are exploring the depths of the ocean or conducting critical subsea inspections, our solution is here to support and enhance your operations. Contact Us Today To learn more about the Subsea Transformer and how it can elevate your subsea missions, contact Poseidon Robotics today. Our team of experts is eager to collaborate with you in shaping the future of subsea robotics and ROV technology. Embrace the power of innovation with Poseidon Robotics!

Buy

In Stock

Manufacturer

New

ASME

Air Freight

![]() Midastream Supply Company in Airdrie

Midastream Supply Company in Airdrie

Storm Choke® K safety valves are ambient-type, wireline retrievable valves with the largest flow area of all direct controlled safety valves on the market. They are ideally suited for high-volume, low-pressure wells. These valves are normally closed and pre-charged with a set dome pressure. When the well flowing pressure drops below the predetermined dome-pressure charge because of a rupture in flowline or surface equipment, the dome pressure and main valve spring close the valve, shutting in the well below the earth’s surface. This valve contains a detent mechanism to provide a positive snap-action closure at the predetermined disaster rate of the valve. Its bore is not restricted by a flow bean. The valve is designed to resist pressure surges. A metal-to-metal poppet valve and seat comprise the valve’s primary closure mechanism. The K valve is ideal for protecting wells with declining bottomhole pressure. This valve closes in situations where a pressure decline would not activate a valve with a flow bean. To reopen the valve, the operator must fully equalize pressure either by applying pressure in the tubing from the surface or by an equalizing prong. The valve will reopen when the tubing pressure acting on the internal piston area overcomes the dome charge. Applications » Wells with declining bottomhole pressure » High-volume, low-pressure wells » Wells with no provisions for surface-controlled valves Features » Poppet closure » Large ports with capacity for high-volume wells » Designed to resist pressure surges *description excerpted from manufacturers catalogue.

Buy

Made to Order

Product

New

API

Sea Freight

![]() Hoca Oil Tools in Zwartemeer

Hoca Oil Tools in Zwartemeer

Streamline Wellbore Cleanout with HOCA Oil Tools' Sand Pump Bailers In the fast-paced and ever-evolving oilfield industry, efficiency and reliability are paramount. HOCA Oil Tools, a leader in innovative downhole solutions, introduces the Sand Pump Bailer – a cutting-edge tool designed for the effective cleanout of sand, debris, and other obstructions from wellbores. This essential tool is part of our comprehensive range of downhole slick line tools, engineered to enhance the safety and efficiency of your operations. Innovative Solutions for Complex Challenges: The Sand Pump Bailer The HOCA Sand Pump Bailer is specifically designed to address the challenges associated with sand and debris accumulation in the wellbore. Utilizing a simple yet effective mechanism, it allows for the removal of obstructive materials, ensuring a clear path for production and extending the life of the well. Constructed with high-quality materials, the Sand Pump Bailer withstands the harsh downhole environment, delivering consistent performance and durability. Elevate Your Downhole Operations with HOCA Oil Tools At HOCA Oil Tools, we are committed to delivering solutions that meet the unique needs of the oil and gas industry. Our Sand Pump Bailers embody this commitment, providing an efficient, safe, and cost-effective solution for wellbore cleanout challenges. With a focus on innovation, quality, and customer service, we ensure that our tools not only meet but exceed the expectations of our clients. Incorporate HOCA's Sand Pump Bailers into your downhole operations and experience a new standard of efficiency and reliability. Choose HOCA Oil Tools for your downhole needs and unlock the full potential of your wellbore operations. Leverage the power of advanced downhole solutions with HOCA Oil Tools. Our Sand Pump Bailers are more than just tools – they are partners in your operational success, ensuring that your wells remain productive, safe, and free from obstructions.

Buy

In Stock

Product & Service

New

API

Air Freight

Gas Tight Casing Patch GTX-SPAN

GTX-SPAN![]() ID OILTOOLS B.V. in Oudkarspel

ID OILTOOLS B.V. in Oudkarspel

Looking for a heavy-duty, permanent solution for sealing splits, holes or perforations in your tubing and casing? Look no further than the GTX-SPAN System Tubing/Casing Patch from ID OILTOOLS! Our GTX-SPAN System is the first effective gas tight patch on the market, thanks to the premium sealing elements in each component. Each element contains two elastomer seals, providing superior gas shut off capabilities. The GTX-SPAN System is incredibly versatile, and can be run on electric wireline, tubing, or coil tubing, and set with a pressure setting tool (electrical, mechanical, or hydraulic). The large bores ensure easy passage of tools and equipment, minimizing restriction to fluid flow. Customizable for most well applications, including premium alloys, restrictions, and geothermal well applications, our GTX-SPAN System Tubing/Casing Patch is the solution you need for your sealing needs. Our system consists of three basic components: a top metal element with an expandable elastomer seal, a tubular extension, and a bottom metal element with an expandable elastomer seal. Various patch lengths can be obtained by adding tubular extensions, making it a modular and versatile solution for any well. During the setting process, the pressure setting tool exerts a pushing force on the top tapered metal swage and a pulling force on the bottom tapered metal swage. Both swages are driven into the metal sealing elements (with expandable elastomer seals), which expand outward into the casing wall, providing both a metal-to-metal and an elastomer seal. At a predetermined force, a calibrated weak point shears, and the setting process ceases. A collapsible setting collet located in the bottom swage retracts and allows the setting equipment to be retrieved. The interval is now fully isolated with metal and expandable elastomer seals. ID OILTOOLS highly recommends the use of a casing scraper before patch installation to rid the interval of foreign matter and the use of a casing caliper to provide an accurate record of casing I.D. and conditions. A gauge ring or drift run is a minimum requirement. Choose the GTX-SPAN System Tubing/Casing Patch from ID OILTOOLS for the first effective gas tight patch on the market. Contact us today to learn more!

Buy

In Stock

Product & Service

New

API

Sea Freight

Hydraulic hoses for industrial equipment applications

Hydraulic Hose![]() Grid Dirt Construction in Red Deer

Grid Dirt Construction in Red Deer

Just like a hose you might use to water your garden, the purpose of a hydraulic hose is to allow fluid to flow from one component to another – in this case hydraulic fluid. The hose is the conduit that ensures the fluid is able to travel unimpeded and it's a vital part of keeping hydraulics systems moving. A hydraulic hose is used anywhere in a hydraulic system requiring a flexible connection between two fluid ports. A hydraulic hose is a synthetic rubber tube surrounded by some sort of flexible strength enhancing winding, such as metal or fiber, and then covered in another rubber carcass. Flow velocity is determined by both the hydraulic pump's flow rate and the hydraulic hose size. Changing the flow rate of the hydraulic pump but leaving the hydraulic hose size the same will affect flow velocity. Standard high pressure hydraulic hose 1SN can in -40°C to +100°C, ID 4.8–50.8mm, OD 11.8–64mm, operating pressure 40–250, burst pressure 160–1000 bar.

Buy

In Stock

Product

New

ANSI

Sea Freight

Coiled Tubing Sliding Sleeve Activator

SSA Sliding SLeeve Actuator![]() Marlin Oil Tools in Calgary

Marlin Oil Tools in Calgary